Quality standard

Quality requirements for adhesive labels.

- General requirements

1.1 Manufactured labels must comply with:

The format, the material selected according to the surface of adhesion, the storage environment.

Uploaded / or self-created layout on the Mark24 website, design elements, text.

2. Quality requirements for adhesive label printing

2.1 Print quality requirements:

Possible misalignment of colours during digital printing ± 0.08 mm (picture no. 1);

Possible misalignment of the cutting line with the print ± 0.5 mm.;

CMYK colour density can vary by ±8% from the numerical value of colour density;

Print “cracking” is possible ≤0.4mm² (or in one printing step, the total maximum area of “cracking” allowed is 0.002% of the print area), the text must be clearly readable;

Raster application, the maximum number of connected raster points allowed is 2 pcs., total quantity ≤ 2 pcs./cm² in the area of the label;

“drops” smaller than 0.15mm² in size, possible total amount ≤1.5mm² (or in one printing step, the maximum total area of “drops” allowed is 0.002% of the printing area);

Unnecessary printing elements smaller than 0.4mm², the possible total amount of no more than 1.2 mm² (or in one printing step, the total maximum area of unnecessary printing elements allowed is 0.002% of the printing area).

2.2 Requirements for varnished labels:

The varnish must be completely and evenly covered;

Varnished labels cannot be printed on by printers, because they will not print.

2.3 Quality requirements for label cutting

The shape must conform to the agreed shape and dimensions;

The base of the label must be clean, not smeared with paint or varnish;

The base of the label must be uncut.

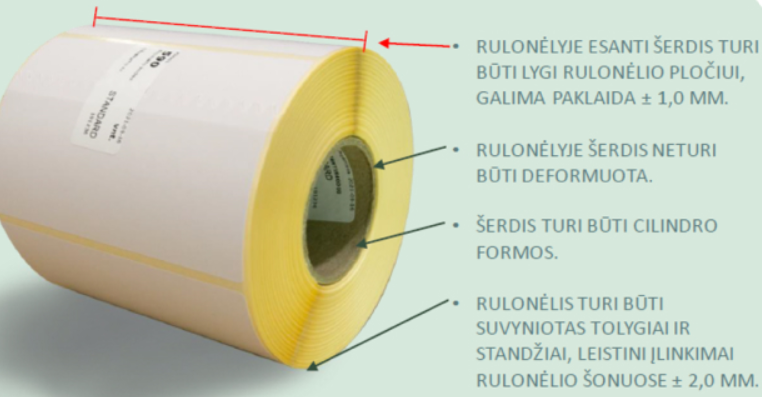

2.4 Requirements for labels rolled into rolls:

Inner diameter of the cores of the rolls 40 mm.;

The maximum outer diameter of the rolls is 100 mm.

2.5 Packing requirements for adhesive labels:

The optimal box format shall be selected depending on the quantity and size of the label rolls;

Several types of label rolls can be placed in one box;

Samples of all labels packed in the box must be affixed to the box;

We put only as many rolls as can easily fit in the box. The box must be well closed and sealed, there can be no deformations and protrusions;

If there is looseness in the box, it shall be filled with protective cushions so that the product does not get damaged.

3. Storage and use of adhesive labels.

Adhesive labels must be stored in a clean, dry warehouse, away from heat/cold sources, protected from direct and indirect sunlight. It is recommended to store in the original manufacturer’s packaging. After unpacking, put them horizontally on the shelves.

The ideal temperature for long-term storage of adhesive labels is from +20 to +25°C; relative humidity 45-55% RH.

Short-term storage conditions: temperature +15 + 30° C and humidity 35 – 60% RH (no longer than 4 weeks); temperature +30 ÷ +40° C and humidity 30 – 70% RH (no longer than 48 hours). If stored longer under these conditions, the warranty period is no longer valid.

If the ideal storage conditions cannot be observed, it is necessary to acclimatize the labels before Use – keep them for at least 8 hours at the temperature where they will be used.

The production date and warranty period of the adhesive labels are indicated on the packaging/box label.

4. Validity/warranty period

The principle of determining the warranty period: for determining the warranty period recommendations of FINAT, the warranty period of the supplier of raw materials, the data of the analysis of customer complaints, the data of the analysis of internal discrepancies shall be followed.

The warranty period for adhesive labels is 12 months from the date of manufacture, subject to the specified storage conditions.

The validity period of the labels is indefinite, but after the warranty period, it is necessary to check the suitability of the quality characteristics of the labels.